The Role of Robotics in Industry 4.0

Automation has come a long way from its humble beginnings in the industrial revolution. What started as basic mechanization of tasks has now transformed into sophisticated technologies that can streamline entire processes. The evolution of automation has revolutionized industries by optimizing productivity, reducing errors, and enhancing safety measures.

As businesses strive for more cost-efficiency and competitiveness, automation has become a crucial tool in achieving these goals. From automated assembly lines to machine learning algorithms predicting maintenance needs, the evolution of automation continues to shape the future of industries worldwide. With advancements in artificial intelligence and robotics, the possibilities for automation are virtually limitless, promising a future where tasks are performed with precision and efficiency.

Enhancing Efficiency in Manufacturing Processes

Automation has revolutionized the manufacturing industry by streamlining processes and improving overall efficiency. With the integration of cutting-edge technologies such as robotics and artificial intelligence, companies are able to optimize their production lines and minimize errors. By automating repetitive tasks and utilizing advanced data analytics, manufacturers can enhance productivity and reduce operational costs.

Smart factories are at the forefront of this manufacturing revolution, incorporating seamless automation systems to improve efficiency and quality control. By connecting various production elements through IoT devices and cloud-based platforms, factories can achieve real-time monitoring and predictive maintenance. This interconnected approach not only boosts efficiency but also enables agile responsiveness to changing market demands, keeping manufacturers competitive in today’s dynamic business landscape.

• Automation has revolutionized the manufacturing industry

• Cutting-edge technologies such as robotics and artificial intelligence are being integrated

• Automating repetitive tasks and utilizing advanced data analytics enhances productivity

• Smart factories incorporate seamless automation systems to improve efficiency and quality control

• IoT devices and cloud-based platforms enable real-time monitoring and predictive maintenance

• Interconnected approach boosts efficiency and enables agile responsiveness to changing market demands

Integration of Robotics in Smart Factories

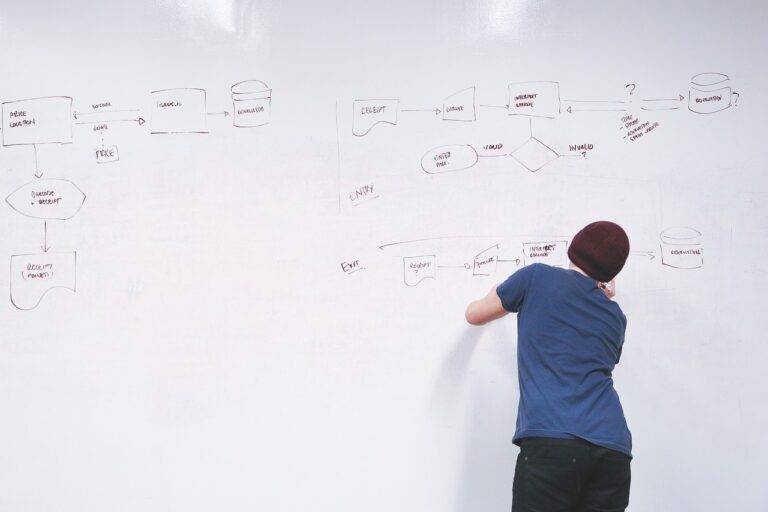

The integration of robotics in smart factories has revolutionized the manufacturing industry. These advanced robots are equipped with artificial intelligence and are programmed to carry out complex tasks with precision and efficiency. With sensors and cameras, they can adapt to their environment and work alongside human workers seamlessly.

Automation using robotics has led to significant cost savings for manufacturers by increasing productivity and reducing errors. Robots in smart factories can work around the clock without breaks, leading to continuous production and faster output. This seamless integration of robotics has not only improved the speed of manufacturing processes but has also enhanced the overall quality of products, meeting the demands of consumers in today’s fast-paced market.

What is the evolution of automation in manufacturing?

Automation in manufacturing has evolved from simple machines to more sophisticated technologies like robotics, AI, and IoT.

How do robotics enhance efficiency in manufacturing processes?

Robotics can perform repetitive tasks with precision and speed, leading to increased productivity, reduced errors, and higher quality output.

What are smart factories and how do they integrate robotics?

Smart factories are manufacturing facilities that use advanced technologies like robotics, AI, and IoT to optimize production processes. Robotics play a key role in automation and data exchange in smart factories.

What are the benefits of integrating robotics in smart factories?

Some benefits include improved efficiency, reduced costs, increased safety for workers, and the ability to adapt to changing market demands quickly.

How can companies implement robotics in their manufacturing processes?

Companies can start by conducting a thorough assessment of their production needs, investing in the right robotics technologies, and providing proper training for employees to work alongside robots.